PrintVision

June 5, 2025

Choosing the right 3D printing method can be confusing—especially with terms like SLA vs FDM vs SLS floating around. Each technology has strengths and trade-offs when it comes to cost, detail, material compatibility, and use cases. In this guide, we’ll compare the three most common 3D printing types to help you make an informed decision.

Understanding the Basics

FDM (Fused Deposition Modeling)

- Most common and beginner-friendly method

- Works by melting and extruding plastic filament

- Affordable, great for basic parts and prototypes

SLA (Stereolithography)

- Uses UV light to cure liquid resin layer by layer

- Produces high-resolution prints with smooth surfaces

- Best for small, detailed models and artistic applications

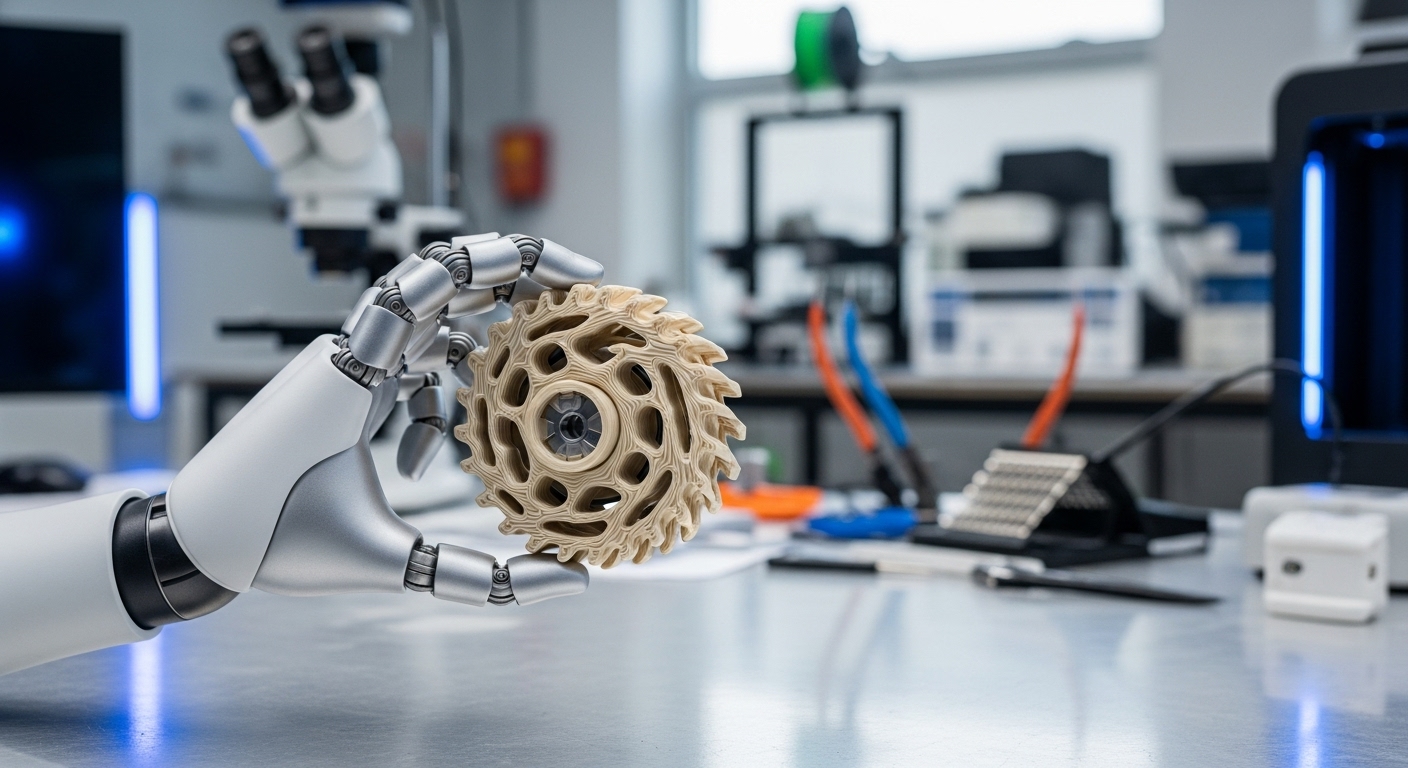

SLS (Selective Laser Sintering)

- Uses a laser to fuse powdered material (usually nylon)

- No need for supports, ideal for complex geometries

- Industrial-grade strength and precision

Comparing SLA vs FDM vs SLS

| Feature | FDM | SLA | SLS |

|---|---|---|---|

| Print Quality | Medium | Very High | High |

| Material Cost | Low | Medium | High |

| Surface Finish | Visible layers | Smooth, detailed | Slightly grainy |

| Strength | Moderate | Brittle (resin) | Strong (nylon) |

| Best For | Prototypes, functional parts | Jewelry, dental, miniatures | Mechanical parts, enclosures |

| Support Removal | Required (manually) | Required (alcohol wash) | Not needed (powder acts as support) |

| Cost of Equipment | $300–$3,000 | $500–$5,000 | $5,000–$100,000+ |

Use Cases by Technology

FDM:

- Brackets, enclosures, jigs

- Affordable hobby and prototype prints

- Educational and personal projects

SLA:

- Dental and medical models

- Jewelry and miniatures

- Mold masters for casting

SLS:

- Functional prototypes

- Aerospace and automotive parts

- Complex moving assemblies

Which One Should You Choose?

- Choose FDM if you need low-cost, fast prototypes or strong prints for daily use.

- Choose SLA if surface detail and aesthetics are important.

- Choose SLS for engineering-grade strength and part complexity.

Tips Before You Decide

- Consider what materials you need access to (e.g., flexible, biocompatible, or food-safe).

- Assess how much post-processing you’re prepared to do.

- Factor in space and ventilation requirements—especially for SLA and SLS setups.

Understanding the differences between SLA, FDM, and SLS is key to choosing the right tool for your job. While FDM offers affordability and speed, SLA delivers precision, and SLS leads in complexity and strength. Each has a place, depending on your project’s goals and constraints.