Author: PrintVision

The intersection of technology and design is producing striking results—especially in the world of 3D printing in fashion and jewelry. What was once reserved for prototypes or runway novelties has now evolved into a practical and creative tool for producing wearable, customizable, and sustainable products that challenge the norms of traditional manufacturing. Why 3D Printing… [Read more]

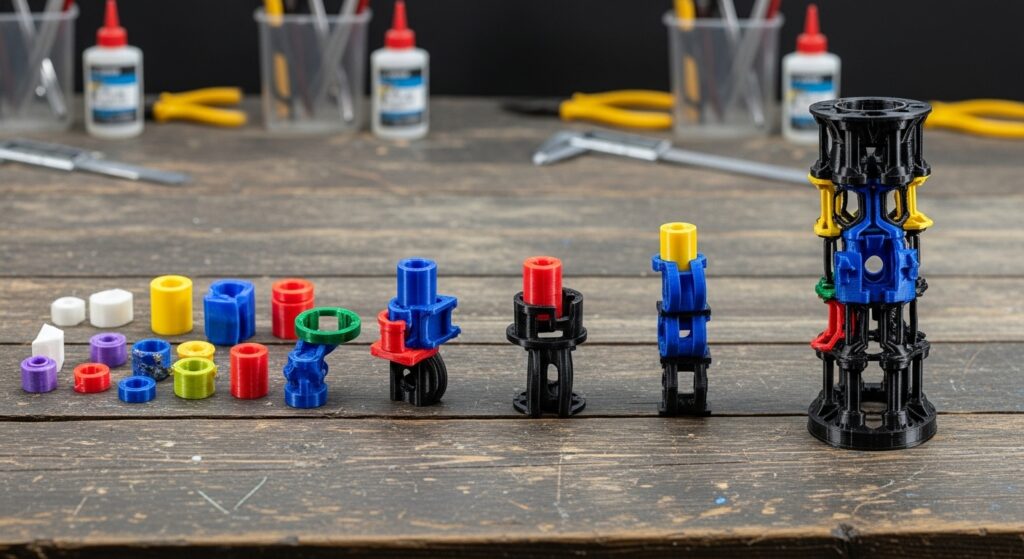

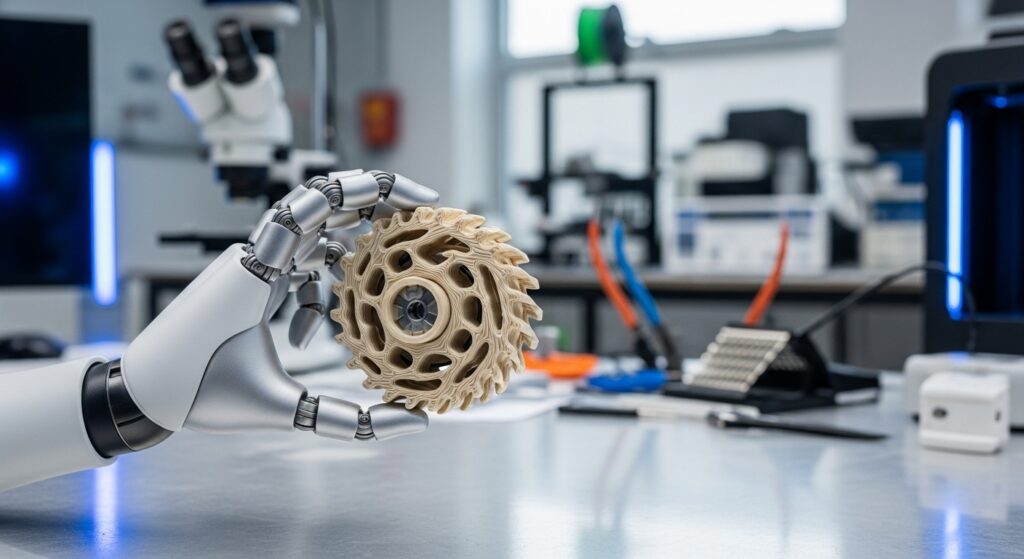

The robotics industry thrives on innovation, agility, and custom solutions. That’s why the use of 3D printed parts in robotics has seen rapid adoption. From research labs to industrial automation lines, engineers are turning to 3D printing to create lightweight, tailored, and functional components that speed up development and reduce manufacturing complexity. Why Robotics and… [Read more]

When it comes to short-run manufacturing, traditional methods often fall short. The high costs of tooling and setup make small batches inefficient and expensive. That’s where 3D printing excels. With zero tooling, fast turnaround, and design flexibility, additive manufacturing has become a go-to solution for producing small quantities of parts—efficiently and affordably. What Is Short-Run… [Read more]

Introduction In 2025, 3D printing, also known as additive manufacturing, has evolved into a mainstream solution for custom manufacturing across multiple industries. From aerospace components to personalized consumer goods, companies are leveraging 3D printing to streamline production, reduce waste, and respond to market demands with unparalleled speed and precision. The Rise of Custom Manufacturing Custom… [Read more]

Choosing the right 3D printing method can be confusing—especially with terms like SLA vs FDM vs SLS floating around. Each technology has strengths and trade-offs when it comes to cost, detail, material compatibility, and use cases. In this guide, we’ll compare the three most common 3D printing types to help you make an informed decision…. [Read more]

Introduction Looking for product ideas to 3D print at home? Whether you’re a hobbyist, DIY enthusiast, or small business tinkerer, home 3D printing opens a world of possibilities. From simple gadgets to useful household tools, there’s no shortage of practical and creative designs you can produce right from your desktop printer. Why Print at Home?… [Read more]

Introduction For startups, speed and flexibility are everything. 3D printing offers a unique opportunity to iterate quickly, validate concepts, and move to market with minimal upfront investment. In this guide, we break down the essential steps for turning your idea into a finished, functional product using modern 3D printing workflows. Step 1: Define Your Product… [Read more]

Introduction The world of 3D printing materials has expanded significantly over the past few years. In 2025, designers, engineers, and manufacturers have access to a wide variety of materials that cater to different industries and use cases. Choosing the right material is essential for achieving the desired strength, flexibility, durability, or appearance in a final… [Read more]

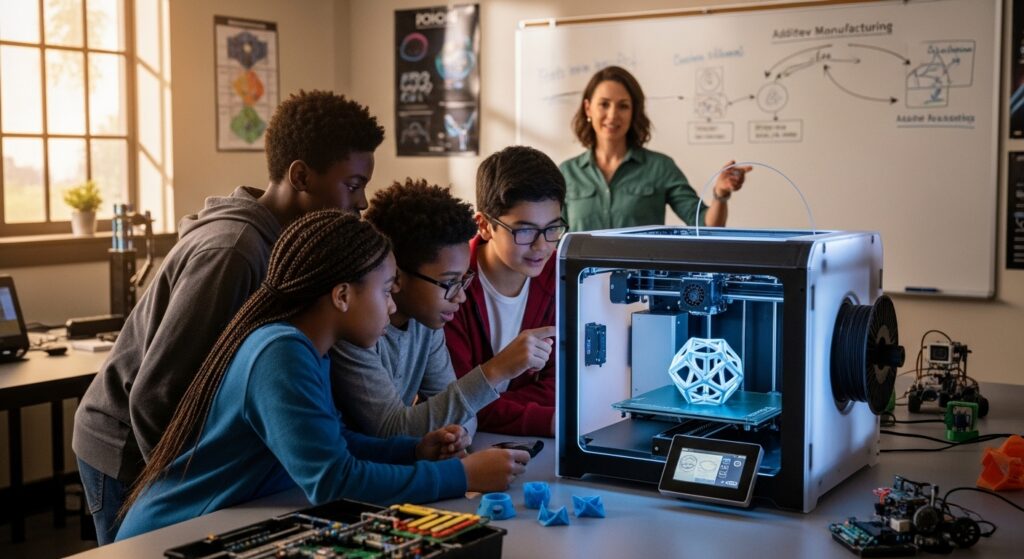

As classrooms adapt to a more technology-driven future, 3D printing is emerging as a valuable educational tool. It brings abstract concepts to life, bridges theory and practice, and sparks creativity through hands-on experimentation. From elementary schools to universities, educators are embracing 3D printing to deepen engagement and make learning more interactive and applied. Key Benefits… [Read more]

Introduction The automotive industry has always been a hub for innovation—and in 2025, 3D printing is steering it toward a faster, smarter, and more sustainable future. Whether it’s prototyping new vehicle designs, creating lightweight components for electric vehicles (EVs), or producing customized parts, additive manufacturing is now central to modern auto manufacturing strategies. Why Automakers… [Read more]