The robotics industry thrives on innovation, agility, and custom solutions. That’s why the use of 3D printed parts in robotics has seen rapid adoption. From research labs to industrial automation lines, engineers are turning to 3D printing to create lightweight, tailored, and functional components that speed up development and reduce manufacturing complexity.

Why Robotics and 3D Printing Work Well Together

Robotic systems often require:

- Complex, non-standard geometries

- Lightweight materials to reduce motor load

- Rapid prototyping during development

- Iterative design and testing

- Small-scale production with tight tolerances

3D printing aligns perfectly with all of these needs, offering engineers a fast and cost-effective way to move from CAD to component.

Key Applications of 3D Printed Parts in Robotics

1. Custom End Effectors and Grippers

Gripper arms, suction tools, and sensor housings can be printed to fit specific parts or tasks—especially in pick-and-place systems.

2. Lightweight Structural Elements

3D printing allows for internal lattice structures or optimized topologies that maintain strength while minimizing weight—critical in mobile or aerial robotics.

3. Sensor Mounts and Cable Management

Flexible, low-volume parts like brackets and enclosures for sensors or wiring can be easily iterated and customized for each build.

4. Prototyping and R&D

During development, engineers can test dozens of iterations in days without relying on outsourcing or costly machining.

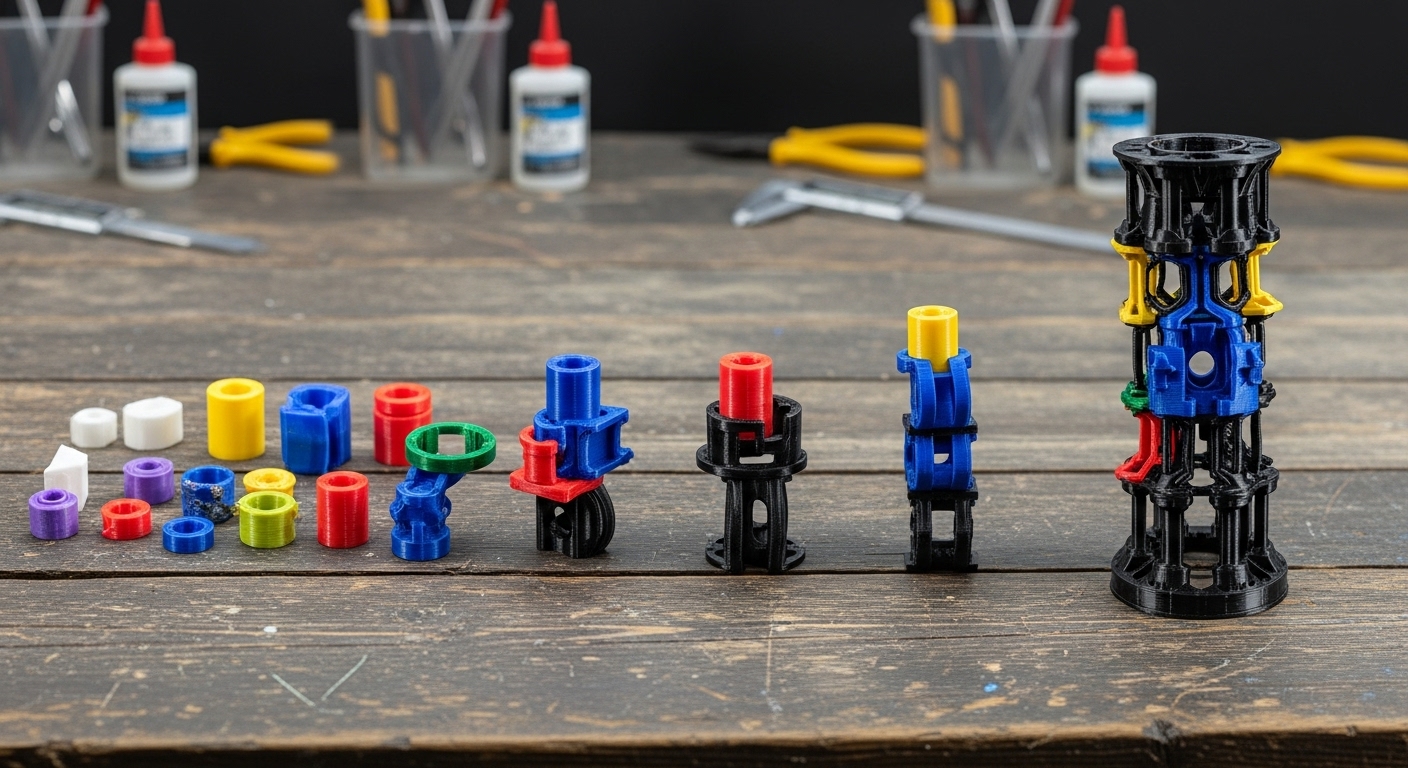

5. Gears, Joints, and Motion Systems

While some high-stress components still require metal, many robotic joints, bushings, or custom linkages can be printed from engineering-grade plastics like nylon or carbon-fiber-filled materials.

6. Modular Components for Educational Robotics

Kits and parts for STEM learning platforms benefit from 3D printing’s accessibility and adaptability.

Advantages of Using 3D Printing in Automation Design

- Reduced Time-to-Market

Faster prototyping accelerates the design and validation cycle. - Design Freedom

Complex geometries, curved surfaces, and embedded channels are easy to achieve. - Supply Chain Independence

Critical replacement parts can be printed in-house to minimize downtime. - Scalability

Short-run or batch parts can be produced without the need for retooling.

The integration of 3D printed parts in robotics is transforming how machines are built, tested, and refined. By offering unmatched design flexibility and faster development cycles, additive manufacturing continues to play a vital role in pushing the boundaries of automated systems.