Introduction

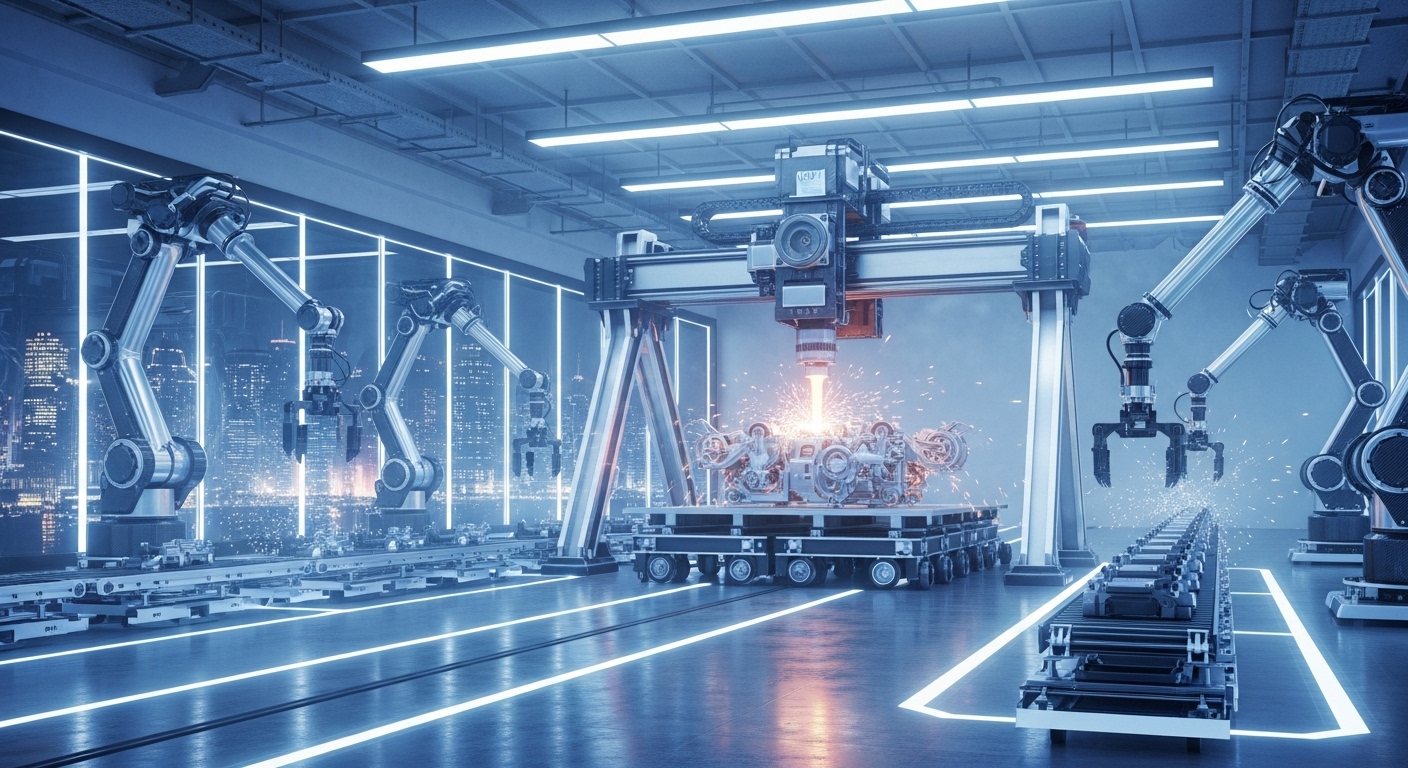

In 2025, 3D printing, also known as additive manufacturing, has evolved into a mainstream solution for custom manufacturing across multiple industries. From aerospace components to personalized consumer goods, companies are leveraging 3D printing to streamline production, reduce waste, and respond to market demands with unparalleled speed and precision.

The Rise of Custom Manufacturing

Custom manufacturing refers to the creation of unique products tailored to specific customer needs or specifications. Traditional manufacturing methods often require costly tooling, lengthy setup times, and large minimum order quantities. In contrast, 3D printing allows for low-volume production runs without the overhead, making it a game-changer for businesses seeking flexibility and cost-efficiency.

Key Advantages of 3D Printing in Custom Manufacturing

1. Faster Time to Market

3D printing drastically reduces prototyping and production cycles. Digital designs can be quickly adjusted and printed, eliminating the need for molds and tooling.

2. Cost-Effective for Small Batches

Unlike traditional manufacturing, where unit costs drop only at high volumes, 3D printing keeps costs relatively stable across batch sizes, making it ideal for one-offs or limited runs.

3. Greater Design Freedom

Complex geometries and internal structures that are difficult or impossible to produce with CNC or injection molding are easily achievable with 3D printing.

4. On-Demand Production

Manufacturers can print parts as needed, reducing inventory costs and minimizing storage space requirements.

5. Material Innovation

From bio-resins to aerospace-grade thermoplastics, 2025 has seen an explosion in the variety of printable materials, enabling a broader range of applications.

Industries Leading the Change

Aerospace and Defense

The need for lightweight, complex parts has driven aerospace firms to adopt 3D printing for both prototypes and end-use components.

Automotive

Car manufacturers are printing jigs, fixtures, and even custom parts for vintage models, reducing costs and lead times.

Healthcare

The medical field uses 3D printing for everything from dental implants to patient-specific surgical guides, improving outcomes and personalization.

Consumer Products

From sneakers to smart wearables, brands are offering bespoke products using 3D printing as the foundation for mass customization.

Challenges and Considerations

While the benefits are compelling, 3D printing does come with challenges. These include post-processing requirements, limited throughput compared to traditional methods, and intellectual property concerns related to digital file sharing. However, ongoing innovation continues to address these obstacles.

Conclusion

As 3D printing technology matures and becomes more accessible, custom manufacturing will continue to shift away from traditional paradigms. Businesses that embrace 3D printing now will be well-positioned to meet the rising demand for personalized, agile, and efficient production.

At PrintVision3D, we specialize in delivering high-quality, customized 3D printing solutions tailored to your business needs. Whether you’re a startup or an enterprise, we help you turn ideas into reality—layer by layer.